by TSgt. Dan Heaton

127th Wing Public Affairs

A group of Airmen from the 127th Maintenance Squadron work together to muscle an A-10 Thunderbolt II engine in to place as they prepare to load the engine on to the aircraft, Sept. 15, 2012, at Selfridge Air National Guard Base, Mich. The engines can be removed from the frame of the aircraft to allow maintenance to be performed on the engine. (Air National Guard photo by TSgt. Robert Hanet) Hi-res

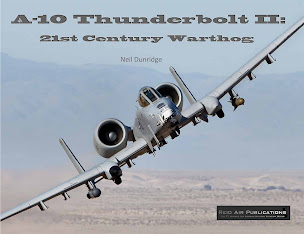

9/16/2012 - SELFGRIDGE AIR NATIONAL GUARD BASE, Mich. -- Like just about everything else on the A-10 Thunderbolt II attack aircraft - best known as the Warthog -- the General Electric TF34-GE-100 turbofan is a big ol' beast of an engine. But even beasts need a little maintenance now and then.

Simple maintenance work can be done on the engine while on the aircraft. More involved work requires the engine to be removed from the aircraft and moved to the engine shop. At Selfridge Air National Guard Base, Mich., it is the responsibility of the 127th Maintenance Group to perform all of the local maintenance on the A-10 and the aircraft's two engines.

"The no. 1 engine on this aircraft was removed to facilitate maintenance," explained Staff Sgt. William Peabody, as he and a team of engine shop Airmen at Selfridge were preparing to replace the engine in the aircraft. A team of six Airmen will work on this project, which took them about an hour or so.

"Really, it is a pretty straight-forward project," Peabody said. "You follow the technical order and everyone working on this has had plenty of on-the-job training working with others."

During the installation, Peabody and Staff Sgt. Dan Stutts worked on top of the engine housing, along with a third Airman who was directing the operation. Two more Airmen worked below the engine to make many of the direct connections of the engine to the aircraft. Finally, a sixth Airman was on hand as a safety observer. Sitting atop the engine housing, which is above the wing on an A-10, Peabody and Stutts used hand cranks to lift the engine - fresh from the engine shop across the street from the flight line at Selfridge - into the housing.

Both Stutts and Peabody each joined the Michigan Air National Guard about three years ago after first serving an initial enlistment on active duty. Both Airmen also served as jet engine mechanics on active duty, but both served in squadrons flying "heavies" - larger aircraft such as cargo haulers.

"There's some specifics, obviously, to each kind of engine and each type of aircraft," Peabody said. "But, for the most part, there's a lot of similarities" between the various types of engines.

The A-10's TF34-GE-100 generates more than 9,000 pounds of thrust - power needed to give flight to an aircraft that carries the heaviest gun - a 30mm GAU-8/A Gatling gun - ever installed an a production aircraft. The engines can power the A-10 to a take-off up to a maximum weight of 51,000 pounds - that's 22,000 pounds of fuel and armaments, in addition to the weight of the aircraft itself.

Stutts, who works as a maintenance supervisor at a defense contractor in the Detroit area, said he enlisted in the Air National Guard after leaving the active duty Air Force because he decided he wanted to continue to be able to serve. After first enlisting in the ANG, he spent several months on training orders working at Selfridge, learning the details of the A-10 and its engines. Stutts said his background working on aircraft in the military helped him to "get my foot in the door at my civilian employer and then I was eventually able to work my way into a supervisory role."

When it comes to changing out the engine on an A-10, Stutts said teamwork is the most important thing.

"Everyone has to work together, because one person could never do this on his own," he said.

True to Stutts' words, after an hour or so of sweating and coordinated activity, the Warthog once again had two engines installed and was ready for a quick return to the flight line.

SSgt. William Peabody prepares a hand crank that will be used to load an engine into an A-10 Thunderbolt II aircraft at Selfridge Air National Guard Base, Mich., Sept. 15, 2012. The engines can be removed from the frame of the aircraft to allow maintenance to be performed on the engine. (Air National Guard photo by TSgt. Robert Hanet) Hi-res

Note: What a great view!!!

Source (including 5 photos)

For more related pictures please check 127th Wing's Facebook album A-10 Engine Install (12 photos)

Please note: More pictures will be uploaded soon.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment