by By Tech Sgt. Emily F. Alley

451st AEW Public Affairs

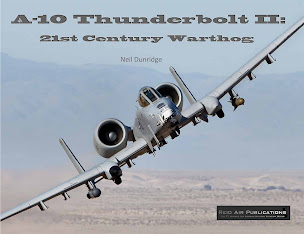

2/25/2011 - KANDAHAR AIRFIELD, Afghanistan -- Every 500 flight hours, each A-10 must go through a phase inspection. In the five months the current inspection team of the 451st AEW has been at Kandahar Airfield, they've completed twenty phase inspections and repaired more than 6,000 total discrepancies.

The inspection might find hairline cracks, missing bolts or chafed hydraulic lines. The inspection is especially necessary for an aircraft that may be older than the pilot flying it.

"This guy could use some dental work," remarked Tech Sgt. Thomas Breining, running his hand over the gray nose of an A-10 where the teeth of this "Tiger Shark" had been chipped away from previous repairs.

Breining and his crew rotate through a different aircraft about every six days at the airfield, which is half the time they would normally take for inspection back at their home station, Moody AFB, Ga. The break between aircraft inspections at KAF has ranged from one week to thirty minutes.

"We take off the panels, look at every item from engines, to flight controls, to each rivet holding on a nutplate for a panel," he described. "The aircraft drives the rest of it."

The specific needs of the aircraft, any discrepancies, merit the attention of the subject matter experts. Fuels, avionics, engines, sheet metal, egress and armament will each send technicians to the phase dock to repair any discrepancies that were identified. Additionally, the non-destructive inspection, repair and reclamation, metals technology and electrical and environmental will take part in phase inspection. Armament inspectors, for example, are responsible for both the gun of the A-10 and munitions racks that are capable of supporting 2,000 pound bombs. Every phase inspection guts the huge ammunition-carrying drum from the plane to inspect it and clean the gun bay.

"We see stuff we don't see at home-- buildup of carbon, wear," described Staff Sgt. Christopher Deem, a combat armament support chief.

In fact, the 451st AEW A-10s set a record for their Area of Responsibility, Afghanistan. From the combined guns of those aircraft, more than 100,000 total rounds were fired within two months in support of troops on the ground in October and November of 2010. Tech. Sgt. Donovan Stinson, a combat armament team chief, estimated that they've seen the heaviest usage in the history of the A-10.

"We're seeing things nobody has seen before," he concluded.

In addition to their primary responsibility in phase inspections, Sergeants Stinson and Deem also respond to emergencies in their aircraft system.

One of the most challenging moments they recalled during their deployment was a weapon malfunction. During a mission, the pilot's gun had a sudden stoppage and wouldn't clear. Once he landed, Stinson and Deem met the aircraft and began to carefully inspect the gun. With live rounds in the chamber, the wrong movement could have caused it to fire at any moment.

The gun is only designed to be fired during flight. The shot is so powerful that if it was fired while the plane was sitting on the ground, the entire aircraft could be knocked on its tail.

"The nose would go up and everyone around would be bleeding from the ears," Sergeant Stinson described.

Finally, they found the problem. The stoppage, they found, was caused by several bolts that had become loose and backed out. The gun is designed to fire almost four thousand rounds a minute and, during training and within the United States pilots try to avoid firing for continuously for more than three seconds.

"In combat, they'll go a lot longer than three seconds," said Sergeant Deem.

After fixing the weapon, they submitted a correction to their technical orders, which are universal books used by all crew chiefs, suggesting the bolts be secured to keep them in place.

The extraordinary amount of wear that Stinson and Deem, and other phase inspectors see at Kandahar Airfield gives them an opportunity to see how the aircraft will respond under the stress, and how it can improve.

Between their hard work at Kandahar Airfield and the maintainers they left at the 23rd Equipment Maintenance Squadron at Moody AFB, Ga, the crew chiefs were recognized with the Hog Star Award on Feb. 8, 2011. It is an annual prize given by the Air Force A-10 System Program Office that recognized the maintainers' innovation and hard work.

"It's a good system," said Sergeant Stinson of the A-10. "It's been around forever. Not a lot of cars the same age are used as much as this plane."

Despite the quality of the aircraft, or any improvements, the inspectors are still meticulous. Unlike a forty year old car, an aircraft can't just pull over when something breaks.

Source

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment