23rd Wing Public Affairs

2/5/2010 - MOODY AIR FORCE BASE, Ga. -- As part of the Air Force Smart Operations for the 21st Century initiative, a Moody squadron recently conducted an event to improve work processes and increase aircraft availability.

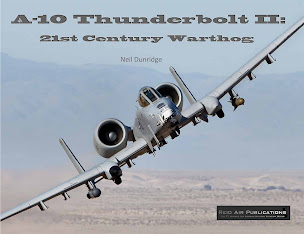

The 23rd Component Maintenance Squadron Egress section conducted a rapid improvement event in an effort to reduce the amount of hours spent inspecting an ejection seat of an A-10C Thunderbolt II aircraft.

"We are required to conduct a full inspection on an ejection seat every 36 months, which usually takes 72 hours," said Master Sgt. Ira Miller, 23rd CMS egress section chief. "Our goal is to streamline our processes so we can reduce the inspection to 48 hours. This allows for less down time of the aircraft and more time for training or other mission-related operations. Although our goal is to speed up the inspection process, we will always provide the best quality inspections."

When the egress section recognized the need for an improvement of their processes, they contacted Master Sgt. Scott Bradford, Moody's AFSO21 program manager, to schedule a rapid improvement event.

The purpose of the office is to teach Airmen the initiative's techniques and applications so they are able to use them in their work centers.

The egress section gathered a team of individuals from career fields involved in the process including sheet metal, crew chief, munitions and air crew flight equipment.

"What makes the use of AFSO21 techniques so effective is that the 'process owners', the workers themselves, are given the power to change the processes that they are involved in," said Sergeant Bradford. "AFSO21 is not about one person deciding the best way to perform a process. It is about a team of experts, in that process, debating and making that decision. Once an action plan is developed by the team, it is briefed to leadership and approved for implementation."

During the rapid improvement event, the team of experts met and discussed the current process.

"With the help of an AFSO21 facilitator, we broke down the entire process to include timeframes," said Tech. Sgt. William Nicholson, 23rd CMS egress assistant section chief. "We examined each task and identified wasteful actions or unnecessary steps."

After the details of the process were examined, the team came up with ideas for a new action plan.

"Some of the ideas included acquiring additional maintenance racks, decreasing the number of seat inspections from four to two by creating a more detailed inspection guideline and replacing the type of cure sealant," said Master Sergeant Miller.

A new action plan was created once the team chose the best ideas for a streamlined process.

"So far, our new action plan has been going well," said Sergeant Miller. "It took the team two days to break down the entire process and create a new one that would streamline our maintenance optimally and I'm impressed with everyone's team work. By this summer, we should reach our goal of 48 hrs, ultimately providing more aircraft to train the pilots.

"Once we fine tune our new technical orders to reflect the change, we will share our success with the egress community across the Air Force," he added. "I think it would be beneficial for them to know a more efficient way to do things."

MOODY AIR FORCE BASE, Ga. -- Staff Sgt. Bryan Flaherty, 476th Fighter Group Air Reserve technician, checks an ejection seat for any flaws or missing parts during a routine check here February 3, 2010. The 23rd Component Maintenance Squadron was able to create a new process to help shorten the inspection process from 72 hours to 48 hours by using techniques and applications from the Air Force Smart Operations for the 21st Century initiative. (U.S. Air Force photo by Airman 1st Class Benjamin Wiseman) Hi-res

MOODY AIR FORCE BASE, Ga. -- Staff Sgt. Bryan Flaherty, 476th Fighter Group Air Reserve technician, observes the bottom of an ejection seat of an A-10C Thunderbolt II while Airman Basic Drake Hoogdorp, 23rd Component Maintenance Squadron Egress section apprentice, reads a technical order during a routine check here February 3, 2010. Sergeant Flaherty and Airman Hoogdorp work together as a team to ensure that the seat is inspected properly in accordance with technical orders. (U.S. Air Force photo by Airman 1st Class Benjamin Wiseman) Hi-res

Source

No comments:

Post a Comment