By Revis Blaylock

The Town Crier

Southworth employees who had a part in the Boeing A-10 project in Manila received a personal thank you Thursday for a job well done.

John Kopp, quality inspector for Boeing, was at Southworth's Manila manufacturing plant as the last of the seven lifts in the Boeing A10 project was being completed.

Southworth is well known for their capabilities of providing special order lifts of all types.

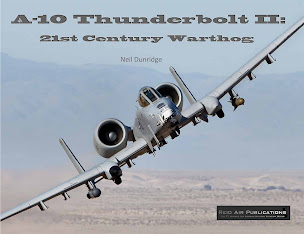

Kerry Pugh, Southworth plant manager, said this was a big project and he was proud of everyone who took part. The lifts will be used in repairing and assembling wings for the Boeing A-10 Thunderbolt airplanes. The Southworth lifts will position workers to assist in the assembling of the wings.

The machine itself weighs 12,200 pounds. It is 8x19' long and lifts workers up to eight feet.

"It is by far one of the largest biggest job we have done," Pugh said. "It has over 2,500 hours work involved at the Manila plant."

New technology was incorporated in the project. The 12,000 pound machine can be moved by one person using the air cushions installed. The air cushions, telescoping hand rails, telescoping ladder, were all new to the workers.

Representatives from Boeing visited the plant in Arkansas and Portland, Maine, (Southworth's headquarters), before the order was approved in June. Southworth had to be qualified as a supplier.

A lot of work went into the project including over 500 individual drawings, over 1,100 engineer design hours, and 375 component drawings. Each lift has 14,071 individual parts, 611 individual part numbers and 125 manufacturing assembly drawings.

The last of the seven machines were shipped on Friday.

Boeing is one of several of Southworth's customers requiring AWS certified welders.

"We are proud of our welders who recently completed the AWS certification," Pugh said. "They had the knowledge and the skill. It was just a matter of going through the process and getting an outside company to test the work of our welders."

Southworth had 10 welders certified including Doug Rose, Jason Winstead, Jason Bressler, David Clapp, Danny Wells, Buddy Pasley, Donald Sammons, Phillip Lindsey, David Cornish, and Dennis Johnson. Johnson also received certification in structural pipe welding.

Pugh and Jim Pry, vice president of operations, expressed their appreciation to the employees.

"We are in the process of getting all of our welders certified," Pugh said.

Sourthworth employees from left, are: Top - Phillip Lindsey, Brian Dawson, Dennis Johnson, Shane Thompson, Donald Sammons, Jason Bressler, Buddy Pasley, David Clapp, Danny Wells, Terry Routon, Michael Spencer. Bottom - Andy Nettles, Eddie Hawkins, David Cornish, Don Spencer, Paul Evans, Doug Rose, Lynn Willmuth, Mitchell Lasater, Wes Curtwright, Richie Pace. Not pictured - Jason Winstead, Bonnie Rogers, Brian Curtwright, Mike Matheny, Greg Martin, Mike Williams, Timmy Brewer and Trevor Huber. (Town Crier photo by Revis Blaylock)

Source

No comments:

Post a Comment