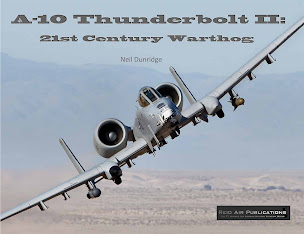

An A-10 Thunderbolt II sits in the 455th Expeditionary Maintenance Squadron hangar for a phase inspection July 2, 2009. Maintainers here have implemented a new phase inspection process that cuts maintenance time on the aircraft in half and ensures the aircraft can provide close air support for ground troops in Afghanistan. (U.S. Air Force photo by Staff Sgt. Jason Lake) Hi-res

by Staff Sgt. Jason Lake

455th Air Expeditionary Wing Public Affairs

7/2/2009 - BAGRAM AIR FIELD, Afghanistan -- In an effort to keep as many close air support aircraft airborne in theater, maintainers here have come up with an innovative phase maintenance process that is being hailed by senior leaders in U.S. Central Command.

A-10 Thunderbolt II maintainers, deployed from the 23rd Maintenance Group at Moody Air Force Base, Ga., have implemented a new process that cuts phase maintenance time on the aircraft in half. The process was key to the 74th Expeditionary Fighter Squadron's A-10 pilots surpassing 5,000 total combat flight hours in May with the help of the 336th Expeditionary Fighter Squadron's F-15 Strike Eagles.

According to Bagram's A-10 phase dock flight chief, Tech. Sgt. Marc Carlson, more than 30 maintainers here thoroughly inspect the A-10 aircraft from top to bottom, inside and out after every 500 hours of flight. At home station, the process takes approximately two weeks and in deployed areas - five days. Here, under a new process, it takes just two and a half days.

"During this inspection, every system and area of the aircraft is inspected and anything that needs to be repaired or replaced is done," said Capt. Dan Vigo, 455th Expeditionary Maintenance Squadron operations officer. "The process here is being performed in two and a half days. The A-10 fleet not only flew all those missions in May, but the average time to phase for the fleet was improved nearly 100 hours higher than before."

One reason for the quicker turnaround is that for the first time, an A-10C unit has used all its back shops in the de-paneling and initial inspection process simultaneously.

"The normal process has the phase technicians de-paneling first, then each of the [back] shops would show up anywhere between days two and four to start inspections," he said. "Under our new construct, every shop starts their inspection as soon as they de-panel their area, thus saving valuable time."

On the front lines, where ground troops come in contact with the enemy on a daily basis, every minute counts. Maj. Pete Lommen, 455th EMXS commander, said it's the maintainers' job to keep enough aircraft airworthy to provide constant overwatch.

"Airplanes break, plain and simple," he said. "These airplanes are more vital than most because they must stay operational to save lives throughout Afghanistan. When they aren't flying, they aren't protecting American and coalition lives."

The process, lauded by Lt. Gen. Gary North, U.S. Air Forces Central Command and 9th Air Force commander during a recent visit here, is already being shared with the next A-10 unit coming into the theater. Master Sgt. Jerry Savoy said this allows the incoming unit to practice on home station aircraft and increase their proficiency with the new process before combat operations.

The 455th EMXS production supervisor is also convinced the new phase process can be applied to similar airframes.

"This phase process will work on any aircraft mission design series," said Sergeant Savoy, a 23-year aircraft maintenance veteran. "It's compatible with not only phase inspections, but the isochronal inspections performed on Air Force heavy aircraft as well."

Staff Sgt. James Cole, 455th Expeditionary Maintenance Squadron structures technician, removes screws from an inspection panel during a phase inspection on the A-10 Thunderbolt July 2, 2009. The aircraft is A-10 81-0964 from the 74th Fighter Squadron. (U.S. Air Force photo by Staff Sgt. Jason Lake) Hi-res

Right: Staff Sgt. Brad Rackley, 455th Aircraft Maintenance Squadron engine inspection technician, inspects an A-10 Thunderbolt auxiliary power unit combustion canister during a phase inspection here July 2, 2009. (U.S. Air Force photo by Staff Sgt. Jason Lake) Hi-res

Left: Airman 1st Class Felipe Madriaga, 455th Expeditionary Maintenance Squadron phase inspection technician, inspects an A-10 Thunderbolt elevator bushing during a phase inspection here July 2, 2009. (U.S Air Force photo by Staff Sgt. Jason Lake) Hi-res

Source

No comments:

Post a Comment